After some quick but very heavy rainfall on Friday evening, we were graced with a beautiful and sunny weekend. The creek sure did its best to try to flood our yard, though!

Earlier in the week a few friends stopped by to drop off another surprise bag full of sheep fleece. I hadn’t fully intended to wash it right away, but I managed to leave the open bag outside in the rain and there is no way I was going to store a bag of wet, dirty fleece for any extended period of time. So, with the sun out over the weekend, I sorted through the fleeces on Saturday to get rid of everything that was extremely dirty, matted, or full of VM, and then on Sunday morning I washed what was left and laid it out in the sun to dry. Of course being outside, I had a little helper who could not keep her paws off the wool.

I don’t have any immediate plans for this wool, but at least for now it is clean and put away. It seems there is significant staining on at least one of them. I thought it had maybe been yolk stain (naturally occurring pigmentation of the lanolin,) but the fact that it didn’t wash out makes me think it could be canary stain – bacterial. Hopefully it hasn’t progressed to the point where it actually started to eat away at the fiber protein, making it weak and prone to breakage, but if the fiber itself is still strong I may still keep it. Unfortunately wool affected by canary stain does not dye well, so overdyeing to hide the color may not work. The fact that the wool still seemed a little gummy or sticky after two washes is also a good indicator that it might be canary stain and unsalvageable. I was in a hurry to get it dried and put away, so I didn’t test it for strength before storing it. I suppose that will now be a problem for future Peter. I really should pull it out again just to double-check. No point in storing it if it won’t be much use for spinning.

While the wool dried in the sun, I brought my spinning wheel outside and had my first official fresh air spin since moving down here. I don’t know why it took me 14 months to do that; it was so nice to sit outside in the sun and spin away!

The outdoor spinning was short-lived, though, because as soon as the sun starts to dip below the ridge line the early Spring temps start to drop immediately and it was time to scoot back inside to keep warm and feed the animals (myself included). As much as I dislike the idea of losing an hour in the morning this coming weekend, I will welcome an extra hour of sunshine after work to spend outside. (I really hope I have that logic right, otherwise I will be severely disappointed.)

While indoors, I spent a few evenings during the week working on setting up a loom to weave a pair of scarves for Kyle and myself. After a brief do-over due to my inability to Math correctly (I accidentally wound a 3.5 yard warp instead of a 6 yard warp and had to hand wind 1000 yards of yarn back onto the cone so I could start again),I was finally able to begin weaving the scarves on Friday night. I didn’t set up my big 40” loom, though. This is my first official project on a significantly smaller 24” 8-shaft loom.

Shortly after moving down here and getting started weaving, I met another guy down the road who was also a weaver! I thought, what luck! I’ve never known another weaver before and somehow, in this town of 600 people, I met another guy who weaves. I thought it would be so nice to know someone else nearby who has a loom. Even more surprising was that our looms were the same brand. Mine is a 10-shaft Macomber with a 40” weaving width, often called a “Big Mac”. His was an 8-shaft, 24” “Baby Mac.” Unfortunately, only a few months after getting to know him, he and his husband moved out of town and he reached out and asked if he could give me his loom because he didn’t really plan on ever weaving again (I know, I don’t understand either.) It would have been rude to say no, so of course I brought his loom home to stay with me.

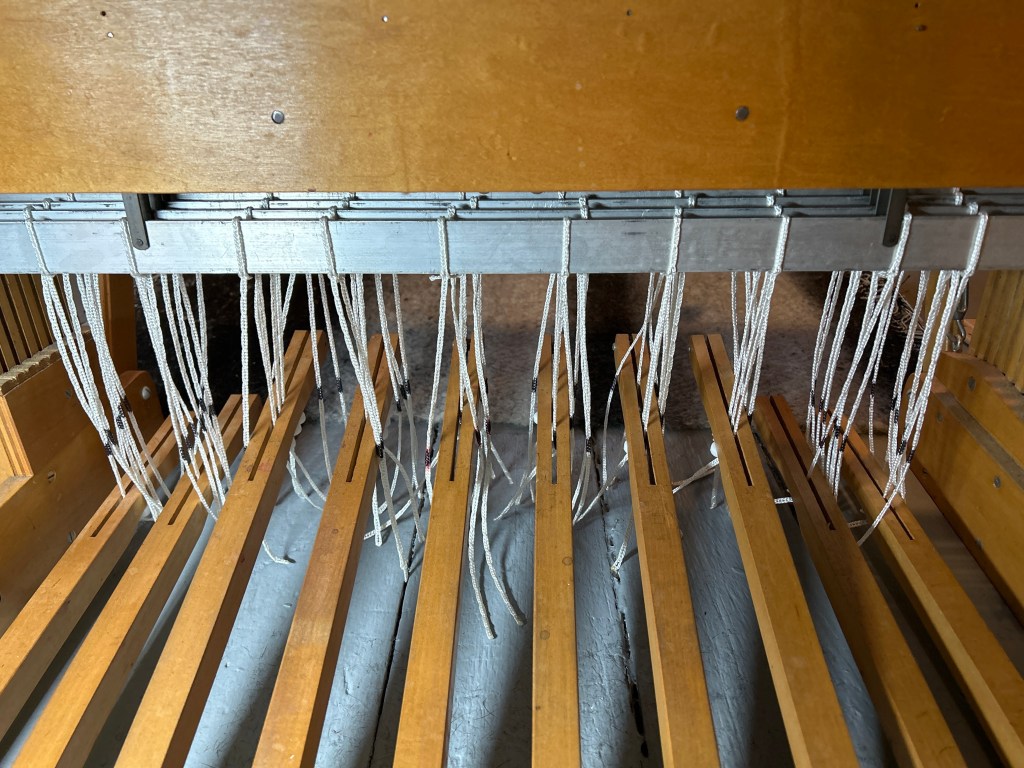

I didn’t have time to take stock of what I needed for the baby Mac when I first took it in, but I finally pulled it out from the corner of the craft room and was able to get it set up to weave. It only had four shafts installed, so the first step was to install the remaining four. I then added about 200 more heddles to the setup so that it can accommodate more warp threads. It only had a handful of treadle hooks, which are used to connect the treadles to the shafts when weaving, so I created my own tie-ups using texsolv – one per shaft per treadle. 8 shafts x 10 treadles means I installed 80 cords, ready for any combination of patterning.

Once all that was done, it was finally ready for me to take it for a test drive. The baby mac has several qualities that I really do like, the first being that it has a much smaller footprint AND is collapsible, making it much easier to move – potentially even mid-project – which could allow me to even weave outside on the porch when the weather is nice. The second is that the shafts are placed within grooves on both sides, keeping them in place and separated from the shaft in front or behind. On the Big Mac, the shafts are free-hanging and when I advance the warp, they tend to get pulled forward and stuck on each other. And the third is that when I ordered the 200 additional heddles, I made sure to get the same style that was already on the loom and because of this I am getting a much cleaner shed on the baby mac than I was on my bigger loom. If you recall, my Big Mac right now is a real mess of heddle styles, which is creating a bit of a wonky shed due to varying thread heights when shafts are raised.

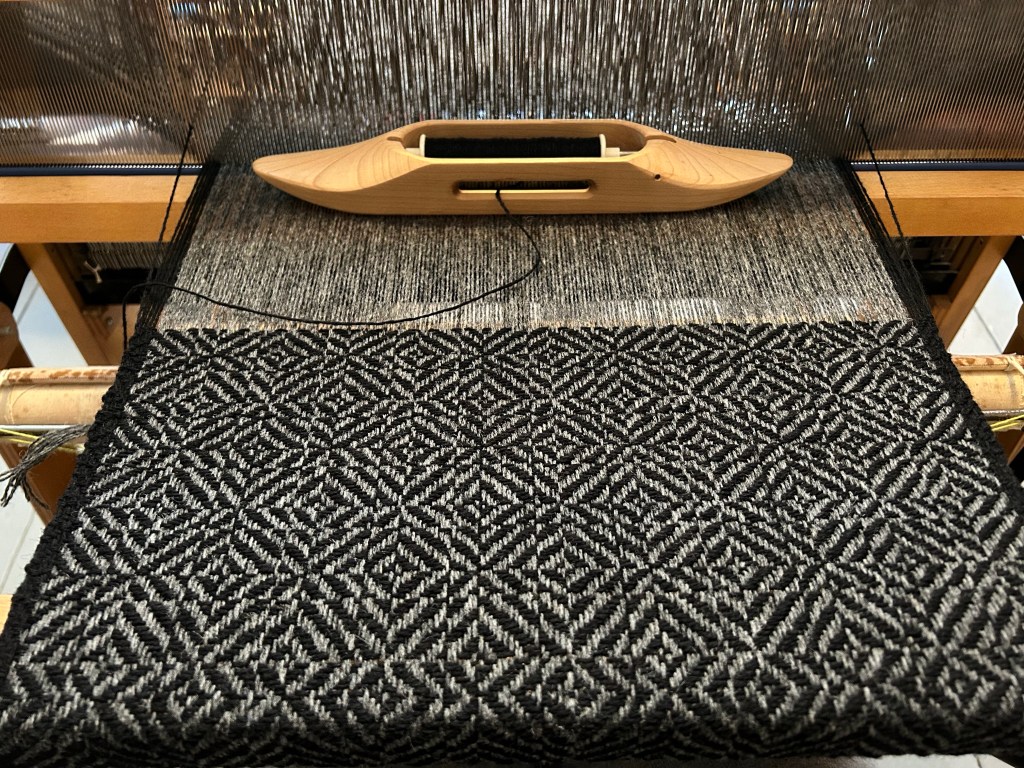

Kyle’s scarf was up first, and I really love how it turned out! I am using Jamieson & Smith 8/2 Shetland wool set at 15 ends per inch for these scarves. Once the loom was set up and ready to go, the weaving flew by and I already got through Kyle’s scarf. Now I am weaving through my own (on the same warp) before I cut them both off the loom to do the finishing.

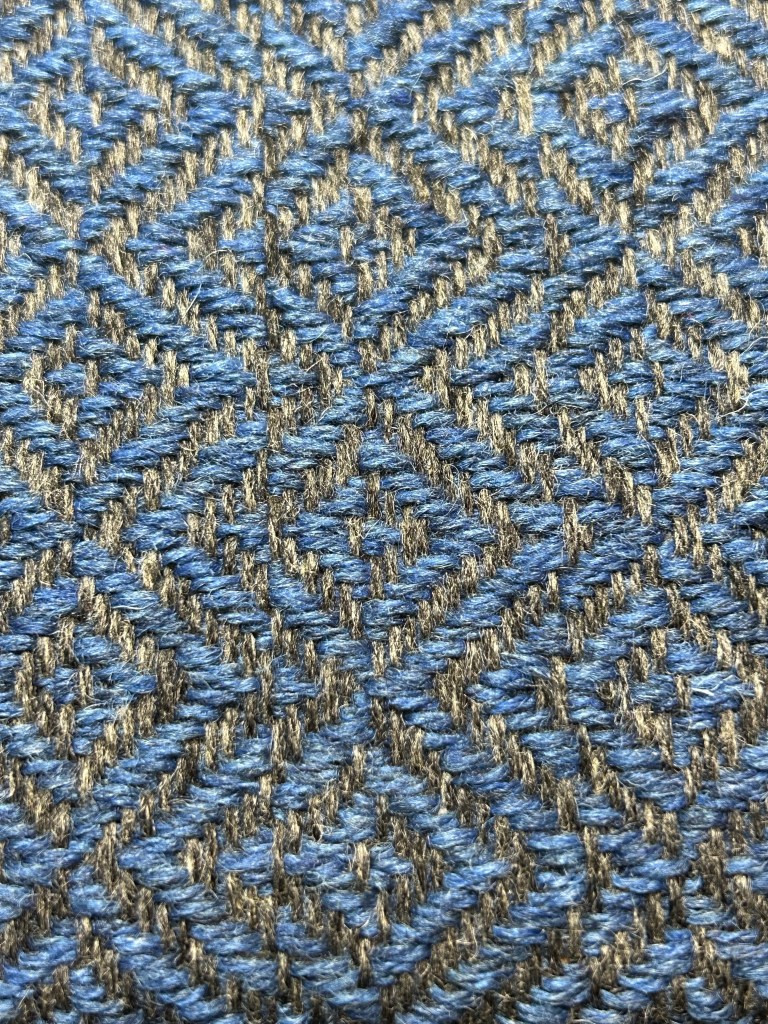

For my scarf, I am using Jamieson’s Shetland Spindrift in Clyde Blue as the weft. I had five balls of this yarn sitting in my stash and thought it would be a perfect way to use it up. The blue and gray are much closer in value than I anticipated, so it is hard to see the patterning but I’m hoping that once the scarves are off the loom and washed it will be easier to see (some natural light will help, too). I modified the patterning for my scarf so that it wouldn’t be identical to Kyle’s, and I am really loving weaving with wool. All of my previous projects have been with cotton and/or linen, and we all know that wool is my happy place.

Hopefully I will be able to finish up my scarf this week and then we can get to the fringe twisting and the finishing work. I can’t wait to see how these look after they’ve had a nice bath and a brushing.

Leave a comment